Apply – Pumps & Compressors

LUBRICATED PUMPS

Oil lubricated vacuum pumps consist of a rotor with grooves in which vanes are inserted, all placed inside a rotor chamber. As the rotor rotates, the vanes emerge from their seat and lap the chamber, forcing the air into smaller and smaller volumes and thus creating a vacuum.

Unlike dry pumps, there is a ring of oil inside the chamber, food-grade or synthetic depending on the application, which allows the system to be more tightly sealed and therefore provide better vacuum performance, from 0.5 to 400 mbar.

In addition, the presence of oil makes it possible to work in humid environments where water vapours may be sucked in.

The main areas of use are: vacuum packaging, thermoforming, glass and marble processing, medical equipment, food or clay paste extruders.

DRY VACUUM PUMPS

Dry vacuum pumps consist of a rotor with grooves in vacuum pumps consist of a rotor with grooves in which vanes are inserted, all placed inside a rotor chamber. As the rotor rotates, the vanes emerge from their seat and lap the chamber, forcing the air into smaller and smaller volumes and thus creating a vacuum.

Dry pumps use graphite vanes: this same graphite, which is atomised by the f riction between the vane and the contact chamber, provides the lubrication that gives good results in terms of operation and durability.

Unlike lubricated pumps, dry pumps do not require maintenance except changing the vanes and cleaning the filters.

However, they must work in environments with clean air flows and no steam.

The main areas of use are: handling with suction cups, automatic machines and woodworking.

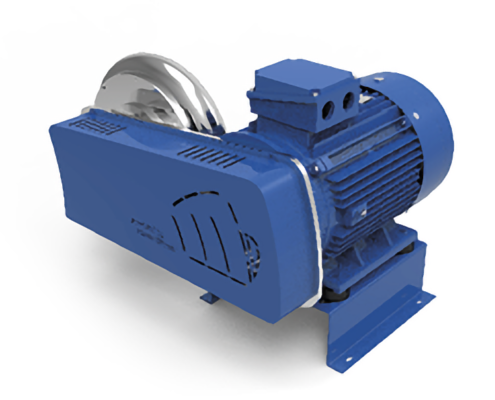

DRY ROTARY COMPRESSORS

Dry rotary compressors require a safety valve to prevent exceeding the stated maximum operat- ing pressure. They are space-saving, quiet and deliver clean, high-quality air without the use of belts or gears. Like dry pumps, maintenance and wear are kept to a minimum.

The main areas of use are: handling, packaging, low-pressure painting, pneumatic conveying, woodworking, food indus- try and water handling, soil oxygenation.

SIDE CHANNELS BLOWERS

Side channel blowers are used for applications that require more pressure or vacuum than a centrifugal blower can provide. They are used to compress or suck non-explosive gases or mixtures and are designed for continuous duty.

Operation

- The pressure of the sucked gas is increased in the peripheral toroidal channel, where the centrifugal thrust of the rotor leads to the creation of a series of vortices. The impeller vanes rotate and, due to the centrifugal force, push the gas forward and also outwards.

- In doing so, the gas undergoes a sequence of recompressions, resulting in an increase in pressure along the channel.

- Overall size and weight are limited and all rotating parts are dynamically balanced to ensure absolutely no vibration.

- They are constructed entirely of die-cast aluminium for maximum strength and ease of handling.

- Further advantages are that they are silent, maintenance-free, easy to install and use and, as they do not require lubrication, the procedures are completely oil-free.

- The side channel blowers can be single-stage or double-stage, with series or parallel connection and with single-phase or three-phase motors.

- Full die-cast aluminum construction for maximum sturdiness and ease of handling. The characteristics data given here refer to the handling of gas with inlet temperature of 15°C, normal density of 1,23 kg/m3 and absolute pressure of 1023 mbar. Tolerance of ±10%.

The main areas of use are: pneumatic conveying for dust, centralised suction for industrial cleaning, suction for CNC workpiece, pick&place with suction cups, water purification, drying with air blades for ceramics, marble, glass.

MASTER BLOWER

Master Blower is an energy-efficient turbine, capable of pushing 20,000 rpm to provide unrivalled thrust and suction power on the market, in terms of space occupied and energy efficiency.

It features high flow rates with very small footprint, high pressure rise, best in class for efficiency and versatility of operation (linked to the wide range of operating frequencies), allowing for the best performance and maximum flexibility in any plant.

Main features

- Peak fluid-dynamic efficiency of more than 80 per cent

- Significant reduction in electricity consumption and installed power

- Stainless steel components for food applications as well

The main areas of use are: drying with lamination (marble, glass, ceramics, beverage, food, …), centralised suction (cleaning and product recovery), PET (plastic granule) drying dryers