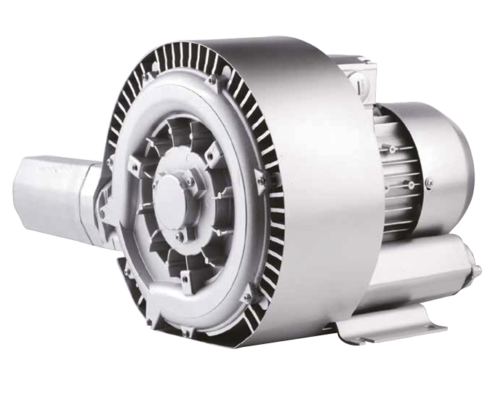

Side channels blowers

Side channel blowers are used for applications that require more pressure or vacuum than a centrifugal blower can provide. They are used to compress or suck non-explosive gases or mixtures and are designed for continuous duty.

Operation

- The pressure of the sucked gas is increased in the peripheral toroidal channel, where the centrifugal thrust of the rotor leads to the creation of a series of vortices. The impeller vanes rotate and, due to the centrifugal force, push the gas forward and also outwards.

- In doing so, the gas undergoes a sequence of recompressions, resulting in an increase in pressure along the channel.

- Overall size and weight are limited and all rotating parts are dynamically balanced to ensure absolutely no vibration.

- They are constructed entirely of die-cast aluminium for maximum strength and ease of handling.

- Further advantages are that they are silent, maintenance-free, easy to install and use and, as they do not require lubrication, the procedures are completely oil-free.

- The side channel blowers can be single-stage or double-stage, with series or parallel connection and with single-phase or three-phase motors.

- Full die-cast aluminum construction for maximum sturdiness and ease of handling. The characteristics data given here refer to the handling of gas with inlet temperature of 15°C, normal density of 1,23 kg/m3 and absolute pressure of 1023 mbar. Tolerance of ±10%.

- The main areas of use are: pneumatic conveying for dust, centralised suction for industrial cleaning, suction for CNC workpiece, pick&place with suction cups, water purification, drying with air blades for ceramics, marble, glass.